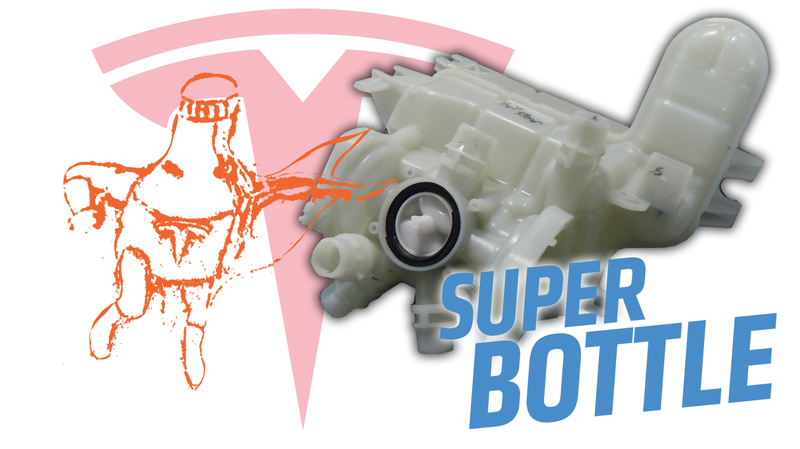

By many accounts, the Tesla Model 3 is a great car. Sure, it’s needed some work on the body and on fit and finish, but there’s lots of cool engineering behind Tesla’s highest volume offering, including the “Superbottle,” an awesome packaging solution for the cooling system that contains a fun little easter egg.

Last week, I stopped by Munro and Associates, the fascinating company that tears cars apart to find out exactly how they’re built. While there, manufacturing experts showed me the Tesla Model 3’s bizarre-looking coolant bottle, which features a cape-wearing bottle as part of the mold:

Also on the bottle is the text “Superbottle”:

The whole design is actually quite interesting. A typical automotive cooling circuit contains a bottle (which is used to fill the system with coolant, and to actively remove air bubbles which could cavitate pumps or cause components to overheat), a pump, some hoses, a heat exchanger, and maybe some kind of valve. Often times, the components are packaged individually, with each having its own mounting provisions and its own dedicated packaging space (plus clearance requirements) usually somewhere in the engine bay.

Advertisement

The Tesla Model 3’s system, though, is different in that it packages two pumps, one heat exchanger, and a coolant control valve all within the bottle itself. Just look at this slick bit of design:

Here’s a closer look at one of the electric pumps:

Advertisement

And here’s the electronically actuated coolant control valve that changes the path of coolant flow:

Not shown in the image above is a computer-controlled actuator—a motor that turns the star-shaped white rod above, and changes the direction of the flow of coolant. Here’s a look at that actuator:

Advertisement

From the top:

Here’s a close-up look at the chiller, which fastens to the side of the Superbottle. The chiller is a heat exchanger between refrigerant and coolant, and its job is to pull more heat out of the coolant than just ambient airflow through a radiator could. This “active cooling” method is used in the industry to keep battery temperatures are their requisite relatively-low temperatures.

Advertisement

To see where the bottle sits in the cooling system, have a look at Munro’s diagram below, particularly the circle with “CR” in the middle (this stands for coolant reservoir). Notice how the bottle is in charge of keeping the battery, drive unit, and power electronics cool by acting as the heart of the cooling system—a hub, so to speak, between components and heat exchangers.

Advertisement

The diagram below, produced by Munro, shows the system when it’s in cooling mode. What I’ve gathered from the image is that coolant that has picked up heat from the battery gets pumped from the rear of the pack into the coolant bottle, then through the bottle-mounted chiller (where heat is removed from the coolant), and then back into the front of the battery pack to capture more of the cells’ heat.

The second pump mounted on the bottle sends coolant through the power electronics (the “management module”), into the drive unit (which includes the motor), then to the radiator to be cooled, then to the bottle before heading back to the management module to pick up more heat.

Advertisement

Per the diagram below, when the batteries need to be warmed up instead of cooled down, you can see that coolant gets pumped to the management module and then into an oil-to-coolant heat exchanger in the drive unit to pick up heat, before being diverted away from the radiator via the integrated valve and sent directly through the chiller (which I assume is off in this case) to warm up the batteries.

Munro says Tesla actually “stalls” the drive motor to intentionally use its heat to warm up the batteries—a novel solution that forgoes the need for an electric resistance heater.

Advertisement

I contacted Tesla to see if the company could tell me more about the setup, and a spokesperson basically told me that, what makes this degas bottle a “Superbottle” is that incorporating a valve, a heat exchanger, and coolant pumps all into one device improves packaging density, and offers advantages in assembly.

Munro echoed these points when I asked for their take on what makes the coolant bottle so special, but also mentioned that the Superbottle could also help reduce vehicle weight, and it could help with serviceability.

Advertisement

Here’s the company’s full breakdown of the Superbottle’s advantages over a traditional setup:

- Increased modularity & packaging space due to the integration of pumps, actuators, and valves with the housing. (Components generally have space protection requirements, separating them could inflate those requirements depending on layout)

- Potential for increased serviceability as functional aspects of the cooling system on collocated

- Potential weight savings associated with portions of those components housing being integrated with Super Bottle. (Separate clamshell housing with standalone/off the self-pumps for a system with comparable functionality and functional requirements)

- Potential weight savings associated with lack separate pumps mounting brackets.

- Reduced final assembly costs, as that likely comes in as a complete module.

- Reduced final assembly time/labor due to component integration & use of quick disconnects is an assembly process enabler.

Advertisement

“Downsides would be,” Munro continued, “increased tooling costs/piece cost; less commonality and reduced potential for volume benefits in terms of pricing,” though a Munro representative did say this is likely the beginning of a new strategy that could be used in upcoming Tesla vehicles or in mid-cycle refreshes of current cars, which could ultimately help bring down piece cost thanks to economies of scale.

For its part, Tesla declined to comment on what this bottle costs compared to a more conventional unit.

Advertisement

In addition to the advantages that Tesla and Munro mentioned, the bottle is just darned slick looking, and from a “perceived quality’ standpoint, that’s got to mean something. It sure impressed me, and I used to design cooling systems.

More photos:

Advertisement

Advertisement

Advertisement

Advertisement