If those numbers aren’t making your internal horseshit alarms beep and wail like aroused banshees, it’s probably time to change the 9-volt in there. But that doesn’t mean there’s not something interesting here, so let’s take a quick look at what we know about the Techrules supercar.

The company actually has two versions of their concept car at the Geneva Motor show, the TREV (Turbine-Recharging Electric Vehicle) AT96 and GT96. The ‘G’ and ‘A’ refer to what the car is fueled by. As they say in their press release:

‘AT’ refers to ‘Aviation Turbine’, indicative that the turbine is configured to run on a liquid fuel such as aviation kerosene, diesel and gasoline. The AT96 is a vision of a track-focused version of the supercar and features management large rear wing, which provides both straight-line stability as well as downforce to aid high speed cornering.

The GT96 – for gas turbine – is designed to run on a gaseous fuel such as biogas and natural gas and is styled as a road-going hypercar.

The cars are both driven by electric motors (six, actually, one per front wheel and two for each back wheel) and the turbine—really, microturbine—is used as a range extender to keep the cars’ 720V/20kW lithium-manganese-oxide battery packs charged.

Advertisement

So, the insane numbers come from a variety of factors. First, the ridiculous power/torque numbers (1030 horsepower, and an insane 6372 lb-ft /4551 Nrp of torque) are broken down like this:

Sponsored

Power output: 768 kW (1,030 bhp / 1,044 PS)

Torque at the wheels:

Front: 2,880 Nm (2124 lb ft)

Rear: 5,760 Nm (4248 lb ft)

Total: 8,640 Nm (6372 lb ft)

Acceleration (0-100 km/h): 2.5 seconds

Max speed: 350 km/h

I mean, with six motors making about 170 horsepower each, you can see how they arrive at these numbers. It’s not unheard of technology, just lots of electric motors crammed in there. That’s not the part that I’m having trouble really buying, though—six motors is absolutely show-car overkill.

The part that’s hard to believe is the fuel-economy numbers. At their claimed 0.18 l/100 km, that comes to 1306 MPG. That’s about five times better than the VW XL1‘s already-astounding 261 MPG, and way better than the similarly electric-with-range-extender BMW i3 REx’s 88 MPG. This is a huge leap in fuel economy, if true.

So, how are they doing it? The secret seems to be that to generate electricity, they’re not using a reciprocating engine—they’re using a turbine.

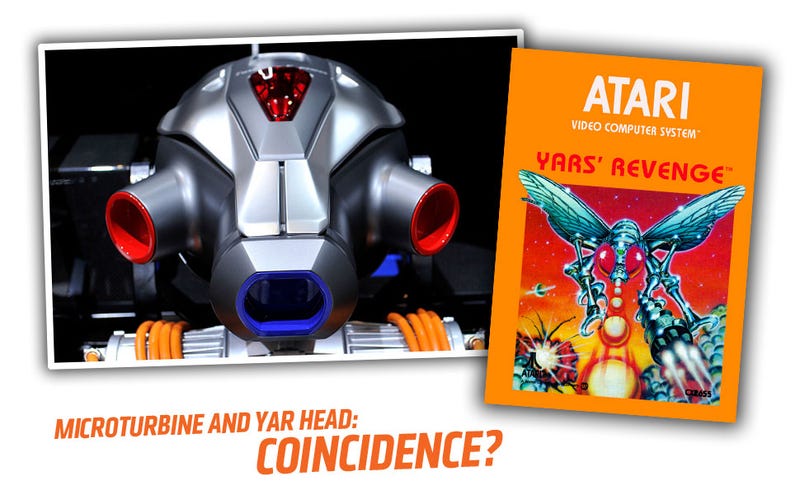

Well, specifically, a microturbine. This is different than the experimental turbine-powered cars of the middle of the last century, which, though they could burn anything from “peanut oil to Chanel No. 5,” weren’t very fuel-efficient, and had searing hot exhaust.

Advertisement

Modern microturbines have developed a great deal, and are much more efficient. A microturbine making the 30 kW Techrules claims is certainly possible, though most commercial microturbines, primarily used for electrical power generation, tend to be between 20 and 30% efficient at turning fuel into electricity. Those numbers are about on par with what a piston-based gas engine would be producing, so unless there’s something I’m not understanding, something else must be going on.

It’s possible Techrules has developed a refined and highly efficient form of microturbine. These machines are very simple and don’t have all that many moving parts, compared to a piston engine, though they do spin significantly faster: 96,000 RPM.

Everything else about this car is, more or less, the usual supercar/concept car sort of thing. If they’re accurate about the capabilities of this microturbine, then we really could be looking at something revolutionary.

They do provide some hints at what makes their microturbine different:

Techrules employs air bearing technology – a high pressure feed of compressed air – instead of a traditional oil lubricant film to separate the shaft from the bearing. This results in fewer frictional energy losses, since it eliminates parasitic losses of a mechanical bearing. The use of an air bearing system is not unique, but how Techrules uses the air bearing involves genuine world-first innovations.

Of particular note is that the air bearing is also supported by a magnetic field that allows for precise adjustment of the high speed shaft. Both bearing solutions work together to maintain exceptional stability. The magnetic bearing allowsa far greater clearance between the shaft and its wall lining, which delivers significant advantages for the long-term durability of the system.

This is an especially important consideration in automotive applications of turbine systems because – unlike in stable power generation conditions – the entire assembly must be able to be capable of withstanding volatile operating conditions that result from, for example, vertical shocks from uneven road surfaces and lateral forces in cornering. Techrules’ hybrid bearing system is also more economic to produce, because the built-in extra clearance space reduces the extreme tolerances usually required.

In addition, a new design of internal foil – an intrinsic component within an air bearing – is used for the bearing liner that supports the air pressure and flow. It is made of a new compound material that gives it superior durability. Of equal importance is that the new foil enables the mass production of the bearing liner at the required production tolerances to be achieved at a high volume scale at low cost.

It should also be mentioned that they’re not the first to employ microturbines into a vehicle; a company called Wrightspeed (started by an ex-Tesla engineer) has been using such systems in garbage trucks for a few years, and they’ve had clients with plans for a 1000 horsepower supercar as well. Plus, they have this video of serious truck hooning:

Sure, Techrules concept sounds impressive, but as it stands right now, there’s zero proof. Techrules says they will be producing some cars for testing and development, so hopefully soon we’ll have some real-world data.

Until then, I’m going to breathe normally. But I’m hopeful.

Contact the author at jason@jalopnik.com.